Introduction to CRTs

Cathode Ray Tubes (CRTs) were once ubiquitous in television sets and computer monitors before the advent of LCD, LED, and other advanced display technologies. A CRT works by using electron beams to illuminate phosphors on a screen. While CRTs are largely obsolete, understanding the chemicals involved in their operation is still important, especially when it comes to their disposal and environmental impact.

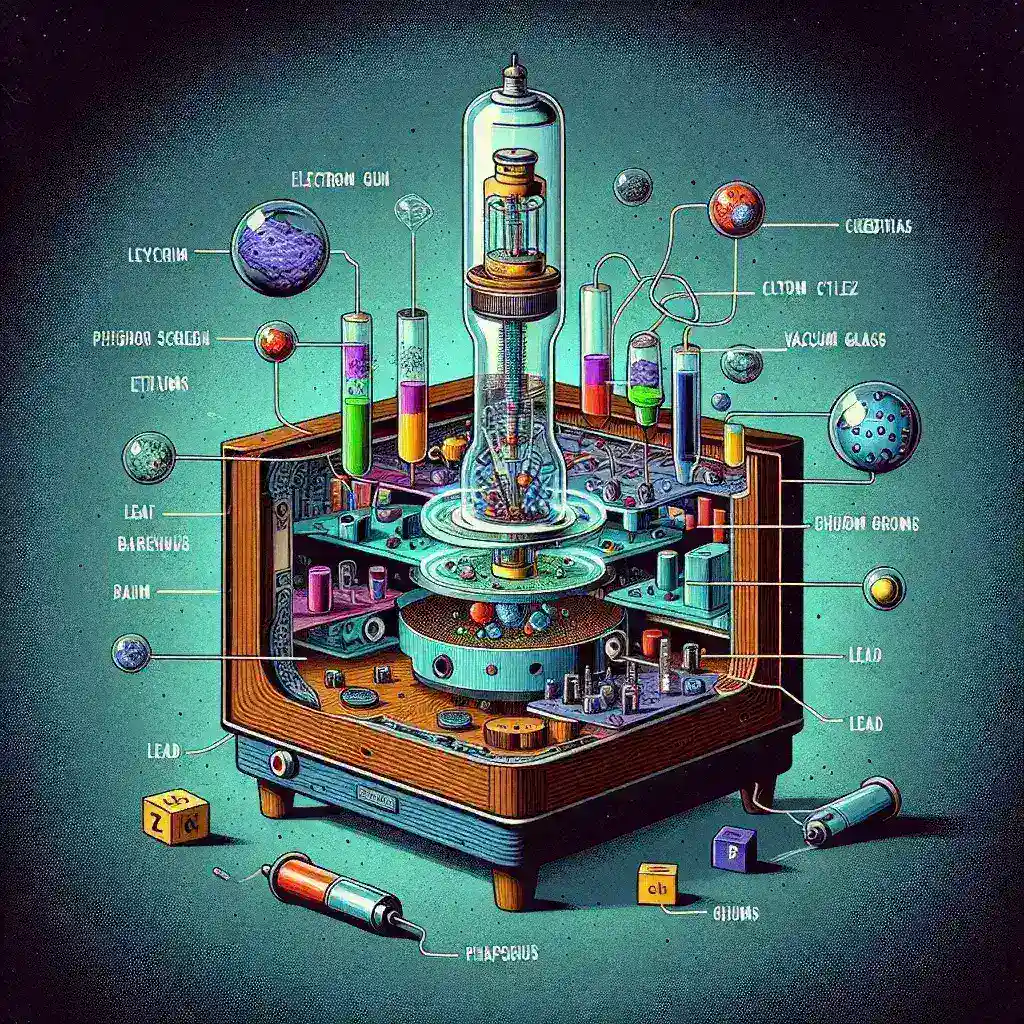

Primary Components and Chemicals in a CRT

The CRT is a complex device that contains several key components and associated chemicals. The primary parts include the glass screen, electron gun, phosphor layer, and shadow mask. These components contain various chemicals that serve different functions within the tube.

| Component | Chemical | Function |

|---|---|---|

| Glass Screen | Lead Oxide (PbO) | Shielding and structural stability |

| Electron Gun | Barium | Electron emission |

| Phosphor Layer | Zinc Sulfide (ZnS), Cadmium Sulfide (CdS) | Emission of visible light |

| Shadow Mask | Iron (Fe) | Directs electron beams |

Glass Screen

The glass screen, which forms the front part of the CRT, is typically infused with Lead Oxide (PbO). Lead oxide is used predominantly for shielding purposes to protect users from X-rays generated within the CRT. It also adds structural stability to the glass, making it more durable.

Electron Gun

The electron gun, located at the back of the tube, emits and directs the electron beams towards the screen. Barium is an essential chemical used in the electron gun. It is often part of a barium oxide coating that facilitates efficient electron emission.

Phosphor Layer

The phosphor layer is what makes the display output visible to the human eye. This layer is coated with various phosphorescent materials, primarily Zinc Sulfide (ZnS) and Cadmium Sulfide (CdS). When electrons hit these phosphors, they emit light, contributing to the image on the screen.

Shadow Mask

A metal sheet known as the shadow mask is employed to ensure that electron beams hit the correct phosphors on the screen. The mask is typically constructed from Iron (Fe), which directs the beams accurately to achieve proper color alignment.

Other Chemicals in CRTs

Beyond the primary components, other chemicals are involved in the manufacturing and functioning of CRTs. These include:

- Yttrium (Y) – Used in red phosphor coatings.

- Antimony (Sb) – Used as a doping agent for certain phosphors.

- Aluminum (Al) – Often used as a coating for the inner side of the faceplate to reflect light towards the viewer.

- Mercury (Hg) – Sometimes found in small amounts in older CRTs.

Health and Environmental Concerns

The chemicals used in CRTs pose significant health and environmental risks if not handled properly. Here’s a closer look at some of these concerns:

Lead Oxide

Lead is a toxic metal that can lead to various health issues, including neurological damage and developmental delays in children. Improper disposal of CRTs containing lead can result in soil and water contamination.

Cadmium

Cadmium is another hazardous metal found in CRT phosphors. It can cause severe lung and kidney problems if inhaled or ingested. Cadmium exposure is a significant environmental concern as it can persist in the environment for extended periods.

Mercury

Although mercury is not commonly found in modern CRTs, it is a dangerous neurotoxin and can lead to serious health issues. Even small amounts can be hazardous.

Proper Disposal and Recycling

Given the chemicals involved, the disposal of CRTs must be handled carefully. Many countries have regulations that mandate the proper recycling of electronic waste.

- E-waste Recycling Facilities – These specialized facilities are equipped to handle and safely dispose of hazardous materials found in CRTs.

- Manufacturer Take-Back Programs – Some companies offer take-back programs where old electronic goods, including CRTs, can be returned for safe disposal.

- Community Collection Events – Various local governments and organizations arrange collection events to facilitate the proper recycling of electronic waste.

Conclusion

Understanding the chemicals in a CRT and their functions is crucial for appreciating the complexity of these older displays. Although CRT technology is largely outdated, the importance of proper disposal cannot be overstated due to the potential health and environmental hazards associated with the chemicals used in their construction. By adhering to proper recycling and disposal guidelines, we can mitigate the risks posed by these hazardous substances.