Introduction

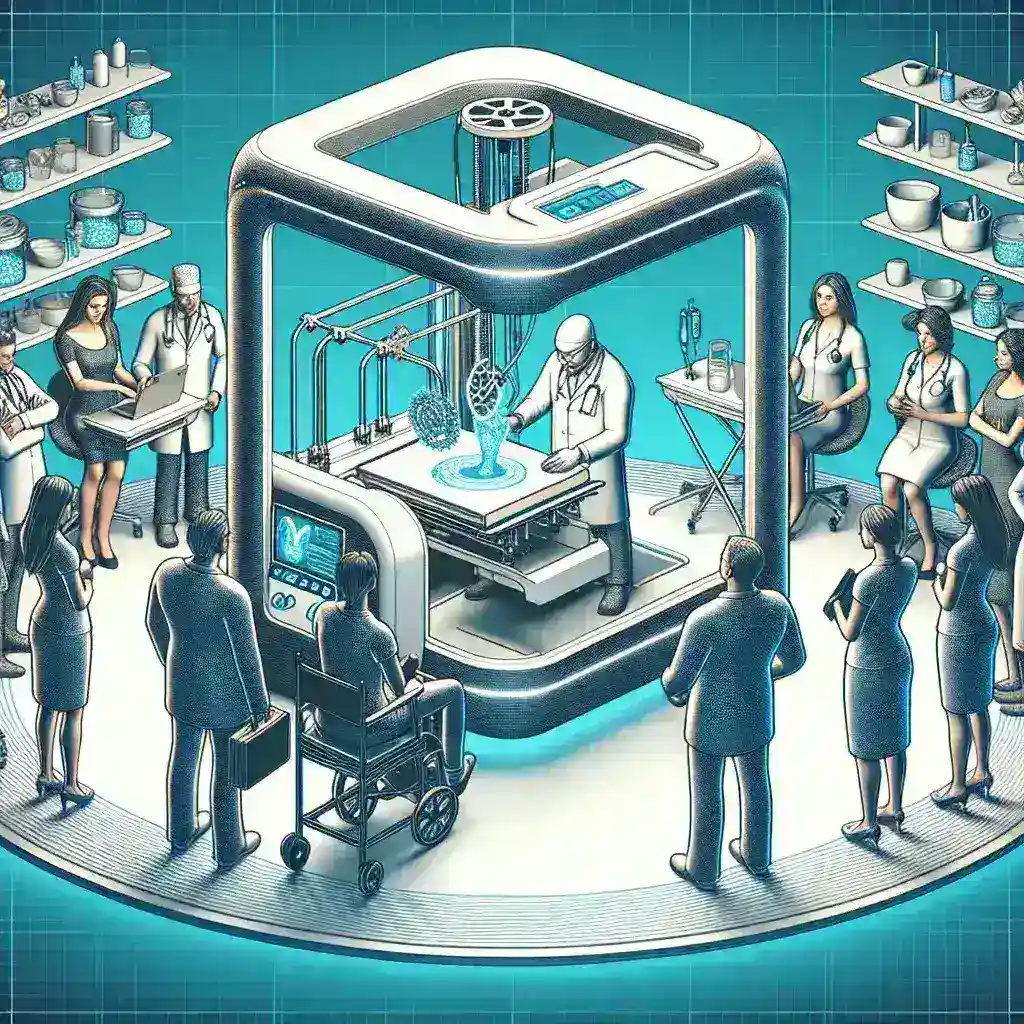

In recent years, the healthcare industry has been witnessing remarkable innovations, and one of the most groundbreaking technologies leading this change is 3D printing. This technology, which enables the creation of three-dimensional objects from digital models, is reshaping various facets of healthcare by enhancing precision, reducing costs, and promoting customization.

What is 3D Printing?

3D printing, also known as additive manufacturing, involves creating an object layer by layer from a digital blueprint. The process can utilize a variety of materials, including plastics, metals, and even biological materials. Its application in healthcare is not just a trend but a paradigm shift that has the potential to redefine patient care.

Applications of 3D Printing in Healthcare

1. Customized Prosthetics

One of the most significant advantages of 3D printing in healthcare is its ability to produce customized prosthetics tailored to individual patients. Traditional methods of creating prosthetics can be time-consuming and costly, often resulting in a less-than-perfect fit.

- Enhanced Fit and Comfort: 3D-printed prosthetics can be designed based on the patient’s specific anatomy, ensuring a better fit and greater comfort.

- Reduced Production Time: 3D printing allows for faster production of prosthetics, enabling patients to receive their devices more quickly.

- Cost-Effective Solutions: By minimizing waste and utilizing less expensive materials, 3D printing can significantly lower the cost of prosthetics.

2. Personalized Implants

The use of 3D printing extends beyond prosthetics to creating personalized implants, which are custom-made to fit a patient’s unique anatomical structures. Examples include:

- Dental Implants: Customized dental implants can be produced to match the patient’s bite and spacing.

- Bone Implants: In orthopedic surgery, 3D-printed bone implants can better integrate with the surrounding tissue, promoting faster healing.

3. Surgical Models and Planning

Surgeons have increasingly adopted 3D printing to produce anatomical models of patients’ organs and tissues. These models help in pre-surgical planning and strategy:

- Enhanced Visualization: 3D models provide surgeons with a clearer understanding of the patient’s anatomy.

- Risk Reduction: Practicing on a model enables surgeons to refine their techniques and reduce the risk of complications during actual surgery.

4. Bioprinting

Bioprinting is an emerging field within 3D printing that involves the use of living cells to print tissues or even organs. This innovative technology holds the promise of:

- Tissue Engineering: Creating tissues that can replace damaged organs or are used for drug testing and development.

- Organ Printing: In the long run, bioprinting may lead to the production of functional organs for transplantation, solving the problem of donor shortages.

5. Medical Devices and Tools

3D printing is revolutionizing the production of medical devices and surgical tools:

- Cuts Development Time: Companies can rapidly prototype new devices, significantly shortening the time from concept to market.

- Adaptable Designs: Tools can be easily modified to fit specific requirements, allowing for innovation and flexibility.

Benefits of 3D Printing in Healthcare

1. Enhanced Customization

The ability to tailor medical products to individual patients is perhaps the most significant advantage of 3D printing. Customization leads to improved patient outcomes as products are designed for one specific context and patient.

2. Cost Reduction

3D printing can significantly reduce costs associated with traditional manufacturing processes, including labor, overhead, and material waste. The affordability of devices enables wider access to medical technology.

3. Improved Patient Engagement

When patients receive personalized medical devices, they may feel more involved in their treatment process. This engagement can lead to higher patient satisfaction and compliance with treatment protocols.

4. Faster Development and Delivery

The rapid prototyping capabilities of 3D printing result in quicker turnaround times for production, giving healthcare providers the ability to respond to patient needs much more rapidly.

5. Innovation and Competitiveness

3D printing fosters innovation within the healthcare sector, as it allows new ideas to be turned into functional products without the lengthy development cycles typical in traditional manufacturing.

Challenges and Considerations

1. Regulatory Challenges

While the potential of 3D printing in healthcare is significant, it also presents unique regulatory challenges. Ensuring that 3D-printed medical devices meet safety and efficacy standards is crucial. Regulatory bodies such as the FDA are continuously working on guidelines for 3D printed medical products.

2. Quality Control

Maintaining quality control in the 3D printing process can be challenging, particularly when using different materials and technologies. Establishing stringent quality assurance protocols is essential to ensure the consistency and reliability of the products.

3. Technology Adoption

The integration of 3D printing into healthcare systems requires investment in new technology and training for medical staff. Some institutions may face resistance to change, hindering the adoption of this transformative technology.

Conclusion

3D printing stands as a testament to how technology can drive change in the healthcare industry. From customized prosthetics to bioprinting organs, the applications and benefits are wide-ranging and impactful. By overcoming the challenges associated with the technology, the healthcare industry can fully exploit the potential of 3D printing, ultimately leading to improved patient care and outcomes. As we look toward the future, the synergy between 3D printing and healthcare promises a new era of innovation that prioritizes personalized medicine and efficiency.